5.4 Operations processes

The operations process at Domino’s involves trans-forming inputs to meet the needs of customers; that is, food ingredients are combined and cooked to create finished meals ready for immediate consumption.

Inputs

There are five main categories of inputs: materials, information, customers, human resources and facilities.

Materials

Domino’s uses a wide range of ingredients as raw material inputs that are transformed. Each pizza base has identical inputs. The dough is made from scratch daily in-store using a prepacked dough mix while the sauce is also premade and delivered to each store to ensure freshness. There is a choice of 40 different pizza toppings, although a standard supreme pizza has seven toppings plus oregano and spring onion.

Information

Domino’s relies on current and accurate information to organise its operations in the most efficient manner. The most significant information input is the recipe for each individual pizza. Pizza-make charts are posted in the preparation area. This ensures consistency, as each pizza is topped correctly. Other information inputs are calorie content and preparation times for each menu item.

Information from online orders is analysed to determine demand for particular types of pizza as well as peak times for overall demand. Customer questionnaires are also used. From this information a Domino’s store can order an appropriate quantity of ingredients and do the necessary pre-preparation to manage peak demand without compromising delivery times. PULSE data management is a critical part of the business’s operations. Information from this software is used to accurately estimate the operations process completion time.

Information about how many orders a store is processing, order size, delivery distances and traffic density is used in an algorithm to calculate the likelihood of a driver completing a home delivery within a 15- or 20-minute time frame from when the confirmation text message was sent to a customer for their order. From this information a Domino’s store can guarantee a delivery time.

Customers

Customers are an input because they are changed from a hungry state to one that is satisfied. Domino’s encourages feedback from its customers because the business aims to meet their specific requirements. Customer surveys, responses to its complaints and compliments form on its website, online cooking blogs and social media comments can provide Domino’s with information to analyse for improving its operations and to determine if there is a demand for new products. For example, the Chef’s Best range pizza was introduced as a consequence of customer feedback.

Human resources

By the end of 2018, Domino’s employed about 1807 people in Australia and New Zealand, and about 50 000 worldwide. Each store has frontline staff, dough makers, pizza makers, cutters, delivery drivers as well as a store manager. Employees are well trained and multi-skilled and therefore able to perform any task within the operations. The most visible are the counter staff and pizza cutter. The pizza cutter ensures that customers waiting in-store witness a final quality check before the meal is handed over.

Facilities

Rather than a centralised factory such as a frozen pizza manufacturer would use, Domino’s has highly decentralised operations. The most obvious of Domino’s facilities are its individual shops, which are relatively small and must use space efficiently. Within each store is the essential pizza-making equipment and facilities to create and distribute finished products to customers. The facilities at each store include:

- dough-sheeting machine

- conveyor oven

- pizza-holding cabinets

- refrigeration equipment.

Equipment and facilities are arranged in a process layout to ensure a smooth flow of inputs through each work station. Finally, Domino’s sophisticated PULSE data management system is a key asset for analysing all aspects of inventory and the operations process.

Transformation processes

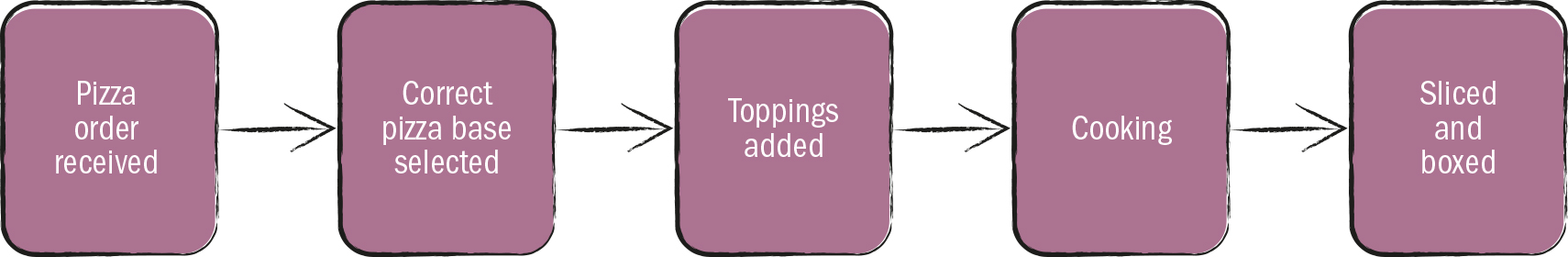

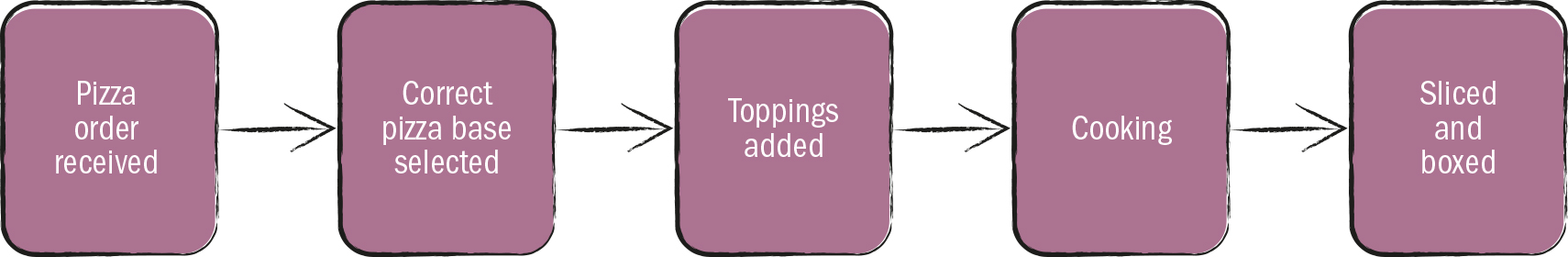

Pizzas are made as individual ‘jobs’ flowing along a production line; therefore, the operations process is more like a large factory using assembly lines. However, each product is customised at the start of the operations process and thus made to order. Large meal orders are processed as a batch to ensure that each item is completed at the same time and to prevent a food item delaying delivery. Pizza bases are prepared in advance for each day’s orders so that these are ready for the start of the operations process. At the pizza make station, ingredients are added in the most efficient order, usually finishing with a cheese topping. The raw pizza in placed in the conveyor oven to cook before emerging as a finished output. The pizza cutter will slice and box up the order ready for delivery. The faster this process occurs, the more orders a Domino’s store can fulfil per hour. Therefore, Domino’s is about to increase the overall productivity of its operations.

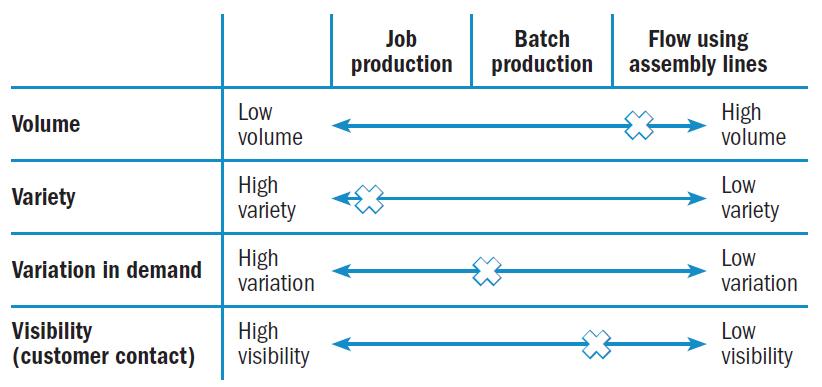

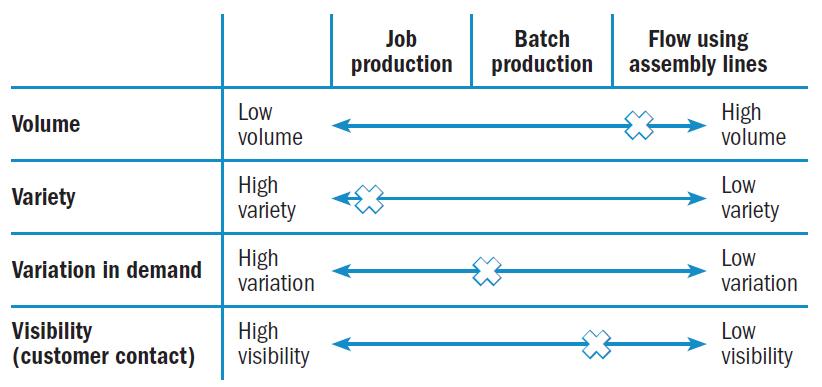

Volume, variety, variation in demand and visibility

Domino’s is no different from other businesses in that its operations are strongly influenced by the four Vs. Being a large company, Domino’s makes over 140 million pizzas a year across its seven markets, with this number steadily rising as the company grows and opens more stores. Each store will have a high volume of output contributing to this figure. However, as there are approximately 100 000 possible ingredient combinations, on seven different types of bases, variety is the most significant influence of the four Vs on operations. Variety is further enhanced through different combinations of items to make up a pizza meal deal.

Overall variation in demand is relatively steady across a year. A typical customer will order at least once in any four-week period. However, sales can be higher during the winter months. Orders tend to be higher during school holiday periods as well. Special events such as sporting grand finals and New Year’s Eve also witness a spike in sales. In a typical week, Domino’s busiest period is Friday and Saturday evenings between 5 p.m. and 7 p.m. Domino’s aims to ‘smooth out’ the variation in demand between Monday and Sunday by promoting its value range of pizzas mid-week.

Visibility is quite high for some aspects of pizza. This is because in-store customers have direct contact with frontline staff and can see their finished pizza emerge from the oven. It is possible in some stores to see preparation staff at work; however, it is unlikely that customers will ever see the full process of the creation of their pizza. Store layouts are being changed to bring the kitchen to the front of the store and therefore increase visibility.

Sequencing and scheduling

Preparation of a pizza must follow a clear order of steps. The sequence begins with the pizza base before ingredients are added in the correct order to ensure quality and consistency. Then the pizza is ready for baking. Task analysis is used to determine the precise sequence in which individual ingredients are added to minimise preparation time. Pizza bases are prepared in advance.

Critical path analysis can enable Domino’s to achieve the fastest pizza preparation times. The critical path is limited by the cooking time of a pizza. However, during this time it is possible to prepare other parts of a meal deal for the customer order or begin a new customer pizza order. This process increases the potential number of orders per hour and reduces time between the customer order and delivery.

Outputs

As a service-based business, Domino’s needs to satisfy the needs of its customers; that is, to deliver pizza to a destination on time, ready to eat. Service therefore also includes interaction with delivery drivers.

As a product-based business, Domino’s has a wide variety of outputs on its menu. There are different types of pizza bases: Classic Crust, Cheesy Crust, Deep Pan, The Edge, Gluten Free, Garlic Bread Crust and Thin'n'Crispy. There are five categories of pizzas: chicken and prawn types, Chef’s Best, traditional and value. In addition, side dishes of bread, chips, chicken and dipping sauces as well as drinks and desserts can be added to create a meal deal. Owing to the option of custom-designing a pizza, it is possible to have over 100 000 varieties.

Overall, there is a 50:50 mix of goods and services.

Customer service

Domino’s aims to differentiate itself from its competitors by providing a level of service that exceeds the expectations of its customers; that is, delivery in time that is faster than customers anticipate which means ensuring drivers are ready to go for delivery from the store to the customer’s door. Another aspect is Domino’s willingness and ability to customise orders and modify meal combinations to suit the individual preferences of a customer.

Given the fact that the industry is already very cost-efficient and there is little difference in prices, a faster level of service and customisation is necessary to gain a competitive advantage. Domino’s aims to increase its share of the home delivery market and achieve year-on-year growth through its customer service strategy.

Warranties

Domino’s stands by its quality claims that customers are guaranteed to get a fresh, hot pizza, and if not satisfied the store will replace it. All food services and businesses providing meals are legally obligated to ensure that products are safe for human consumption. Food safety is governed by the Food Standards Australia New Zealand Act 1991. Under this legislation Domino’s must have correct controls in place throughout its supply chain to ensure food safety. These controls cover receipt, storage, processing, display, packaging, transportation, disposal and recall of food. For example, raw ingredients must be refrigerated. In addition, all employees must receive correct training to ensure that health and hygiene practices are followed. Other requirements under the law concern premises and equipment, and food transportation vehicles. These requirements are designed to eliminate any risk to consuming a Domino’s product. In addition, all allergen and nutritional information is published on its website. Although Domino’s offers vegetarian and gluten-free pizzas, it cannot guarantee that no cross-contamination will occur.

Another aspect of Domino’s guarantee is that participating stores offer a 15- or 20-minute delivery time for an extra charge. If Domino’s cannot fulfil an order or fails to deliver on time, customers are provided with a voucher for a free pizza. Currently, the lead time from order to delivery is approximately 17 minutes. However, Project 3-/10 has the objective of pizzas being made within three minutes of the order coming in, and getting to the customer in 10 minutes. This objective would make Domino’s delivery time faster than Uber Eats or Menulog.