6.2 From heavy to hi-tech

As most developed countries have experienced a decline in heavy industry in the last 25 years, new industries, with vastly different requirements in terms of location and workforce, have sprung up. Jobs in heavy industry have been replaced by employment in hi-tech companies, including information technology, specialised electronic and advanced manufacturing, and in other sorts of industries, such as financial services and communication-based businesses. These hi-tech industries are described as footloose.

While heavy industry was tied to a particular location as a result of the need for raw materials such as coal, modern hi-tech industries, such as software development companies, can be far more flexible in their choice of location. There are, moreover, several key factors that are attractive to these types of industries, as is shown next.

-

.jpg)

Source 6.5 Hi-tech industries can be flexible in choosing manufacturing locations. -

.jpg)

Source 6.6 Heavy industries are tied to a particular location due to the need for raw materials.

Communication

Many hi-tech industry hubs are established along communication routes that allow quick and easy movement of workers and goods. Close proximity to airports is also considered important as many of these companies are global businesses. Fast and available broadband and cable networks are also a necessity for this type of business.

Close to a skilled workforce

Hi-tech businesses are only successful if a suitable workforce of highly qualified employees is available. As a result, these businesses are often located close to major universities.

In or near attractive natural environments

Because attracting the right skilled workers is vital to these businesses, offering the chance to work and live in an attractive environment is also important.

Close to other hi-tech businesses

This allows the sharing of services, greater exchanges of ideas and innovations, and reduced transport costs for components.

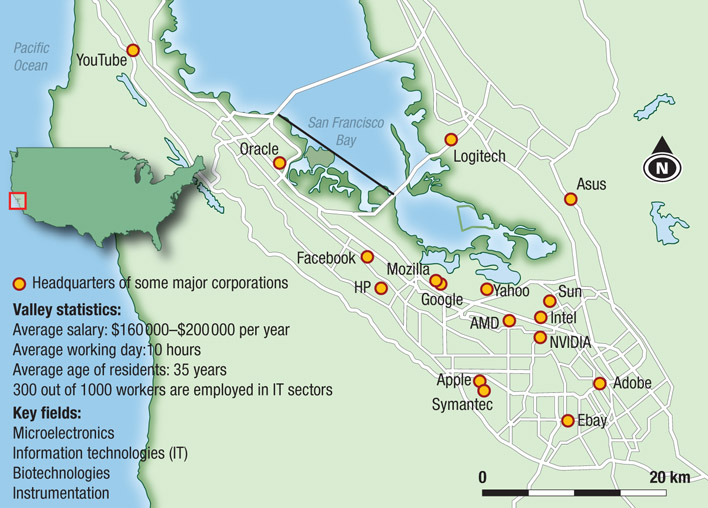

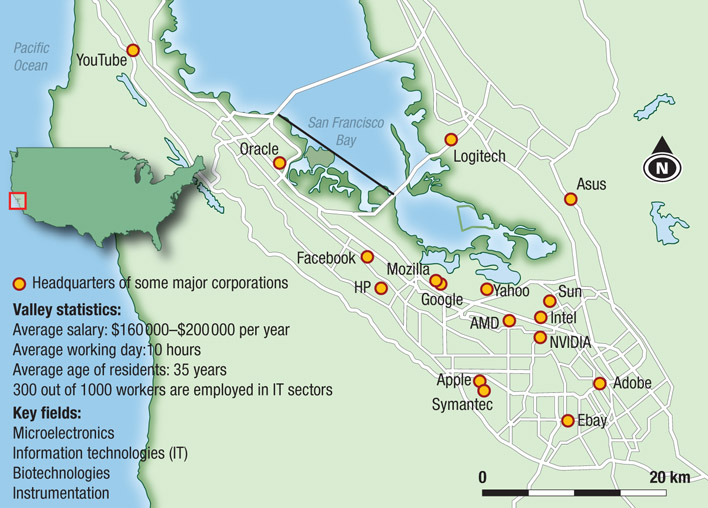

Hi-tech industry in Silicon Valley

The area in California known as Silicon Valley is the biggest and most famous example of an area dominated by hi-tech industry. With around 300 000 workers in these industries generating $200 billion in turnover each year, this region is vital to the United State’s economy.

Silicon Valley has been a key centre of the computer industry since the late 1970s, and the explosion in home computer ownership can be linked directly to its growth. In 1975 around 3000 computers were sold to the public. In 2012 around 330 million were sold worldwide. Most of these were produced by companies with roots in Silicon Valley.

The massive increase in access to and use of the internet has benefited the region, with many hundreds of companies providing online services, servers and software. But why is this region so attractive to these companies?

Causes of its success

Stanford University, located nearby, is considered one of the main factors in the success of the region.

The university, backed by government funding in the 1950s and 1960s for defence research, founded a research park in the grounds of the university that attracted hitech companies. Many of the graduates went on to form highly successful companies in the region. In the 1970s and 1980s, research on computers and the initial development of the internet took place at the university, leading to a large skilled workforce living locally.

The Bay region of San Fransisco has an attractive climate and interesting natural scenery, and is well known for its laid-back lifestyle. Many of the companies adopted such a culture, and firms such as Apple and Google became renowned as model employers, attracting the most talented workers from across the globe. Highway 101, running through the valley, provides a fast and direct communication link between the area and San Francisco.

While a number of the companies located in the valley are huge, most are small businesses with few employees. This has led to a culture of sharing and collaboration between companies, and this has helped make this region home to many leaders in innovative technology. It has given them the edge over other regions that are characterised by larger, more secretive business operations.

With the success of companies such as Apple, Silicon Valley became home to a large number of venture capitalists. Because 40% of all venture capital in the United States is invested in the region, small businesses are attracted to the area – the chances of attracting investment are higher there than elsewhere.

Effects of hi-tech industry in Silicon Valley

Impact on regional and national economies

If California were a country, it would have the eighth highest GDP (Gross Domestic Product) in the world. This illustrates the size and importance of California’s economy both to the United States and globally.

The technology companies of Silicon Valley are a hugely important sector, contributing roughly $40 billion of the state’s $168 billion in exports, as of 2012. This huge sum of money, combined with the fact that the area is home to most businesses attempting to start up, makes its success vital at both a regional and a national level.

Living in the area

Hi-tech industries have had many positive effects on Silicon Valley. Employment rates are higher, and local governments collect large amounts of tax from industries in the area. As Silicon Valley has developed, the area has become home to a large number of the super-rich. The 2012 floating of Facebook instantly created 1000 millionaires in the valley.

The demand for skilled workers has also pushed average wages up. While this attracts workers, demand for housing also pushes prices up. The price of rental accommodation is 78% higher here than the United States average, and the purchase price of a typical house is up to three times the country’s average. This makes it hard for those not working in these high-paying sectors to live in the area.

Traffic congestion and loss of farmland as companies continue to expand in the region are other concerns; this changes the pristine environment that attracted many to live in the area in the first place.

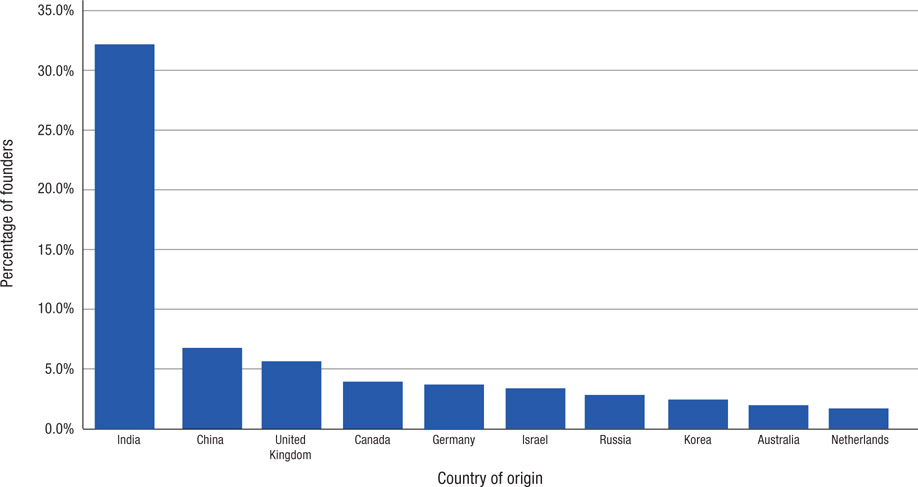

Migration to Silicon Valley

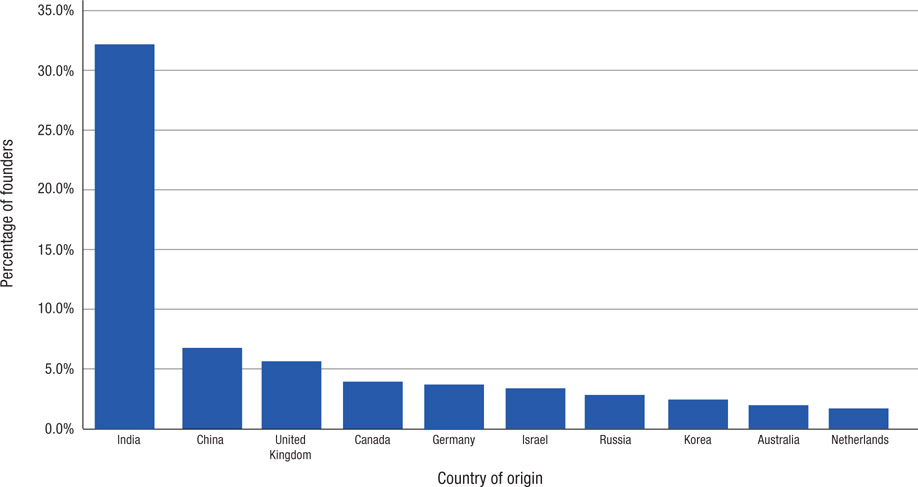

As technology companies continue to hand-pick the best and brightest graduates from around the world, Silicon Valley has become among the most multicultural regions in the United States.

Over half of the scientists and engineers working in the region come from overseas (see Source 6.9). This has given the region a unique cultural identity, as well as a competitive advantage in terms of the level of innovation occurring. However, these workers are more mobile than workforces associated with traditional industries, and they are now moving to other locations, including Pittsburgh, where the cost of living is low.

Silicon Valley and globalisation

Migration is an important element of the success of Silicon Valley, but the region’s relationship with other countries is more complex than just the movement of workers. Many of the larger companies within the area, such as Apple and IBM, are transnational companies.

This means that, as wages in the area and the price of land continue to rise, some operations can be shifted overseas. Apple, for example, made all its products in the United States until 2002. It has since shifted production to countries such as China. Apple still employs over 18 000 people in the United States, but up to 700 000 workers in factories in other countries, subcontracted by Apple, are taking on its manufacturing.

Also, highly skilled engineers and software workers are heading back to their native countries to use the skills learned in Silicon Valley.

Companies in countries such as India are now employing these workers to lead their own hi-tech operations. Conversely, Europeans are coming to Silicon Valley to try to start up operations, taking advantage of the infrastructure and venture capital – they may leave the region later.

DEVELOPING YOUR UNDERSTANDING 6.3

- Summarise the difference between heavy industry and footloose industries.

- Describe and explain two factors that influence the location of footloose industries.

- List key factors for the success of Silicon Valley as a centre of hi-tech industry.

- Explain why Silicon Valley is one of the most multicultural regions in the United States.

- Create a digital map, using Google Earth, that highlights the geographical features that play a role in Silicon Valley’s success. Label Stanford University, Highway 101, distance to the CBD of San Francisco, and the location of the headquarters of Google, Facebook and Hewlett Packard. Write your own description of the relevance of each of these.

The future of hi-tech industry in the United States

Export of hi-tech jobs

Many are concerned that the trend of computer-based industry heading overseas will continue, particularly as cities such as Bangalore in India continue to attract investment in these areas. Also, there are millions of graduates emerging from India’s and China’s universities, which is adding to the concern, as wages and costs are lower in both those countries. Others argue that Silicon Valley’s culture of innovation will create new opportunities and markets in the United States. They use the example of social networking websites that didn’t exist 10 years ago and now employ tens of thousands of people.

Footloose employees

Advances in technology have increased the ability of people in a variety of jobs in a huge range of sectors to work from home. As fibre optic technology improves communication, this may well make the physical location of a workforce less important. This is particularly relevant in the IT industry, where many of the jobs revolve around the use of computers and the internet anyway.

Global companies may have employees in India, the United States and China collaborating on projects in real time.

Advanced manufacturing

Hi-tech and sophisticated manufacturing still exists in the United States and it is expected to continue to grow. One of the most exciting developments is the emergence of 3D printers.

These machines can ‘print’ products, and as they increase in sophistication many feel this type of manufacturing may replace traditional factories.

These machines are already being used to make tools for existing factories, so it is possible that they will one day replace the factories.

Source 6.10a A 3D printer working in plastic. (00:11)

China: rising giant of industry

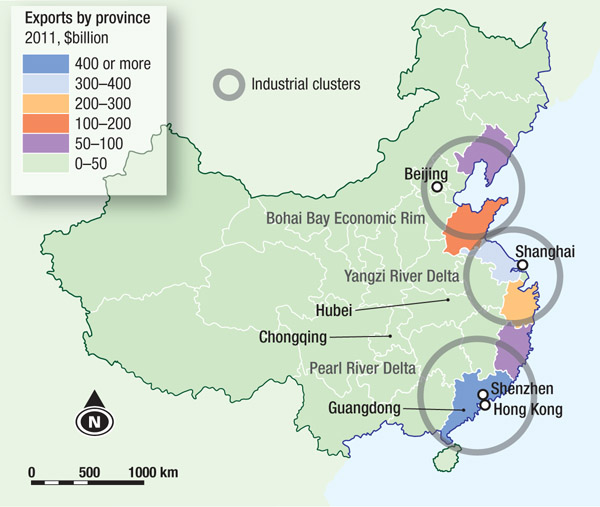

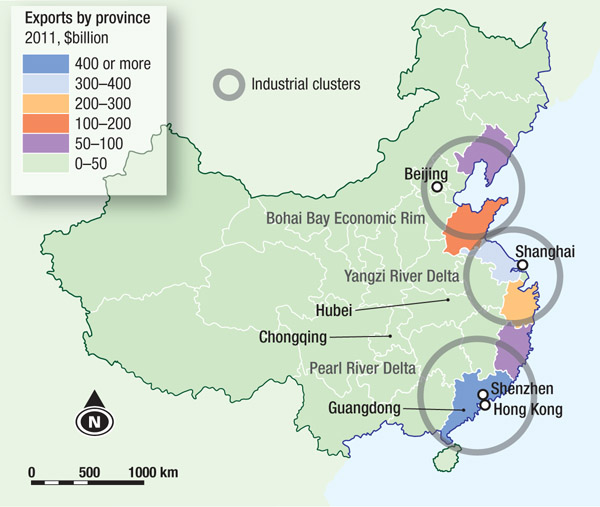

In 2011 China took over from the United States as the country with the largest industrial output, producing over 20% of all manufactured goods globally. Its rise in this sector of the economy has been rapid, with spectacular growth in a wide range of industries, most notably in the last 20 years.

Reasons for the growth of Chinese industry

With a population of around 2 billion, China has both a large available workforce and a significant domestic market for manufactured goods. Also, China’s position in the centre of Asia means it is close to a large number of strong economies, such as Japan and India, which are valuable trading partners.

Developments in agriculture have reduced the need for large numbers of rural workers, which has led to rural–urban migration.

China is a one-party communist state with a very high degree of central control and, until recently, no private ownership of property or companies. It has planned its industrial growth carefully, with all large investments in technology and infrastructure being made by the state. In the last two decades the government has taken a different approach, trying to attract investment from foreign companies through the establishment of Special Economic Zones (SEZ) where taxes and restrictions on import and export are removed.

Wages are lower in China than in Western countries, and laws regarding the conditions of workers and environmental regulations are generally weaker. These combine to reduce the cost of goods produced, which has made those goods very competitive on the world market.

China’s economy

Prior to 1975 China’s economy was dominated by agriculture, although there was some manufacturing, with an emphasis on heavy industry such as chemicals – these were used to make fertilisers, which increased agricultural production. In the last 20 years manufacturing has become the dominant force, as a result of government plans to increase this sector.

China now manufactures a huge variety of goods, including clothing, cars and trucks, electronics and, increasingly, advanced technology such as computers and mobile phones.

China produces 50% of all the cameras made in the world.

While a lot of goods produced are exported, China’s huge population and growing wealth mean there is also a large domestic market now able to afford an increasing range of products.

Manufacturing goods

Most of China’s industry is based in the coastal regions (see Sources 6.11 and 6.12). This, unsurprisingly, is where most of the population is to be found. These areas were settled early, before industrialisation, as they provided trading links, fertile soils and a ready water supply. These regions are also attractive to industry, because:

Source 6.12 Population density map of China

- Coasts provide ports to import raw materials and export goods.

- The east coast is close to major markets such as Japan, and is the start of shipping routes to the United States.

- There are large local populations that provide both a workforce and a market.

- The area has a good water supply for industry and domestic use through major river catchments.

- There is flat land suitable for building factories.

These areas were also targeted in the setting up of Special Economic Zones, largely as a result of the factors outlined above.

Inside a Chinese factory

While conditions in factories vary considerably, depending on the location, owners and the type of goods being made, there are certain characteristics that many of the factories share.

Large numbers of workers

Many factories have thousands of workers, with some huge plants, such as the Foxconn plant in Shenzen that makes goods for Apple, having in excess of 300 000. These numbers illustrate both the scale of manufacturing that takes place and how cheap labour is. In China it is still often cheaper to employ humans than to purchase the machinery to replace them.

Contracted by Chinese or Western companies

Unlike in Australia and the United States, most of these factories are not owned by the companies that they manufacture goods for. They are owned by other, smaller companies that compete for short-term contracts, which reduces both the risk and the costs for the company offering the contract. It also allows the factories to operate several contracts at once. For example, one US computer company may want 300 000 screens for monitors, and another may order 100 000 laptop screens. These may all be produced in the same factory at the same time. The downside for the factories is that they have to be extremely competitive, which always means increased pressure on workers – longer working hours and low wages.

Over 150 million Chinese people work in manufacturing factories.

Highly flexible practices

One key reason for the success of Chinese manufacturing is the rate at which they can change their methods of production. Because it is easier to tell humans to change what they are doing than to re-engineer computerised production lines, companies can change the products, and increase or decrease rates of production extremely quickly. When demand for the iPad soared in 2010, the factory contracted to produce parts for them simply increased the number of workers on shifts to meet that demand.

Conditions inside Chinese factories

Compared with what we expect in an Australian factory, conditions in many Chinese factories are extremely hard. Workers do not have the same rights in terms of maximum working hours and safety conditions. They are sometimes made to work overtime, having to sign agreements with the factory that may lead to up to 100-hour working weeks. There have been cases of workers being forced to stand on production lines for up to 11 hours without a break. One factory was caught fining workers for going to the toilet.

Many factories have dormitories and free or cheap meals, with workers effectively sleeping and working at the factory. This is because even now many of the workers come from rural areas, and so need somewhere to live.

While the Chinese government has made efforts to improve the working conditions in factories and carry out more rigorous inspections, the factories themselves are often highly secretive about their practices. Some companies from developed countries that produce their goods in these factories also try to conceal where their products are being made, partly so that the buying public do not find out about the working conditions in those factories. Although the conditions are tough, many workers stay because they feel the conditions and pay are still better than those in rural areas.

In 2012, 2000 workers at a Chinese electronics factory rioted over working conditions, requiring 5000 police to restore order at the factory.

DEVELOPING YOUR UNDERSTANDING 6.4

- Describe how China’s economy has changed in the last 20 years.

- State two physical and two human factors that affect the location of China’s industry.

- Explain how the working conditions in Chinese factories increase profits for Western companies.

- Discuss the ethics of Western businesses using Chinese labour.

Effects of the growth of manufacturing in China

The rapid and sustained growth of China’s economy has had a range of economic, social and environmental impacts on the country.

Rapid increase in wealth of the population

Despite cheap labour being one of the main factors behind China’s economic growth, wages paid to manufacturers are roughly three times what they were in 2005. This has led to a rise in living standards for all those working in factories. At the other end of the scale, China is now producing a class of ‘super-rich’, as owners of businesses profit from the strong performance of Chinese companies.

In 2013 one in 150 people in Shanghai was a millionaire and there were 90 billionaires living in the city.

As the population gets richer, their demand for goods such as cars and electronics, along with real estate, also increases. Factories and workers are needed to supply this demand, and this increase in production, which means more money is being paid and being spent, makes the economy grow yet stronger.

This increase in wealth does not affect the whole of the population, however. Those still in rural areas earn on average less than $500 per year.

Rural–urban migration

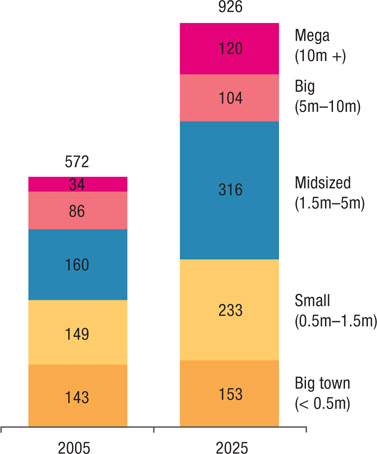

The movement of people from poor rural areas to cities is perhaps the most dramatic effect of China’s economic transformation. In China in 2010 there were around 150 million migrants from rural areas living in urban areas – around seven times Australia’s total population!

This has a range of effects. A significant number of these migrants are unable to find work, which leads to an increase in the number of urban poor. Most of these migrants are young, between 18 and 35, and may be granted only temporary status to stay in the cities. The government sometimes limits them to stays of between 1 and 3 years: the plan is to manage growth and ensure that there are not too many workers for the jobs available.

The map in Source 6.15 illustrates how dramatic this shift in population can be, with provinces such as Chengdu losing over 10% of its population in 10 years, and regions such as Dongguan increasing at a similar rate.

Source 6.15 Internal migration within China

Rural–urban migration stories

Liang is 62. He lives in a village in Guangxi province in southern China, where he tends to crops on steep terraces. Liang has two children, but both have headed to cities to work, one to Hong Kong and one to Shenzhen.

Although they said they would return, they are now earning three times what he earns. He is worried that there will be no one to take over the land, or look after him and his wife when he gets too old to work. Almost all the young people in the village have left, although a few have returned with money. His home has no running water and it is a 20-kilometre trip to the nearest doctor.

Jiao is Liang’s daughter. She is 37. Jiao works in a clothing factory in Shenzhen, and her husband works collecting recycled bottles around the city. They have a son, Hui, who is 17. Most of their spare money goes on school fees for Hui, who they hope will study and become an accountant. Their apartment is cramped, only 15 square metres, and rents have risen a lot in the last few years. Jiao’s husband suffers from respiratory diseases as a result of working outside in the pollution. Although Jiao works long hours, she thinks she will stay in Shenzen as the money is better. However, if she saves enough she may return to her village.

DEVELOPING YOUR UNDERSTANDING 6.5

- From the two accounts make a list of ‘push factors’ (things pushing people away) from rural areas and ‘pull factors’ (things attracting people) to urban areas.

- From Jiao’s account, make a list of advantages and disadvantages of living in the city.

- Suggest why young people should stay in their villages.

- List the benefits of migrating to urban areas.

- Imagine you were living in a rural village and have left it. Write a letter to your father explaining why you left and explain what your life in the city is like. Use the other sections of the chapter to help you.

Rapid urbanisation in industrial areas

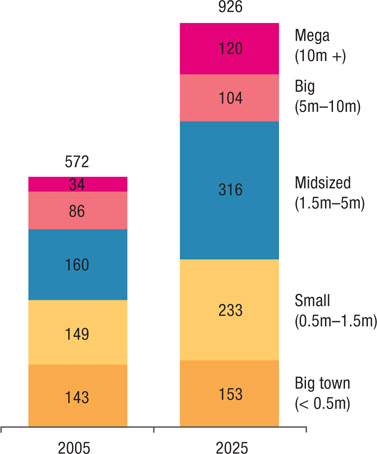

As the graph in Source 6.17 shows, almost 1 billion Chinese will live in cities by 2025. That is the equivalent of creating around 400 cities the size of Adelaide in just 20 years. While many of these people will earn higher wages, and some aspects of their life may be improved, there are also a number of negative impacts associated with rapid urbanisation, including pressure on water supplies, issues with pollution, and lack of services such as health care and schools.

As migrants move into areas in large numbers, and businesses continue to open up to take advantage of China’s industrial strength and development, rapid urbanisation has occurred.

Environmental effects of industrialisation in China

The rapid industrialisation that has occurred in China has caused some extreme environmental problems. While these problems also occurred during industrialisation in countries such as Britain in the eighteenth century, the huge scale of industrial output in China has led to more severe problems in terms of air and water pollution, as well as concerns over the burning of fossil fuels and carbon emissions.

Air pollution

Air pollution in China occurs as a result of both emissions from heavy industry and the burning of coal in power factories. Sulfur dioxide and particulate matter are estimated to kill over 600 000 people in China every year.

Air pollution in China is so severe that it has started to change atmospheric conditions in some areas, reducing rainfall and affecting the ability of vegetation to grow. Acid rain is also an increasing problem – it has been linked to the increasing number of cars in China. Neighbouring countries, including Japan, have seen forests destroyed as a result of acid rain created in China.

Water pollution

Up to 40% of China’s river systems are considered to be suffering severe pollution. The main causes of this pollution are industry – chemicals and waste products – and inadequate waste systems in urbanised areas.

Responses to pollution in China

Until recently, China has done relatively little to reduce pollution levels, arguing that other countries industrialised without strict pollution controls and they should be allowed to do the same. In the last 5 years, though, the government has conceded that something must be done and stricter monitoring and restrictions on emissions have been put in place. The Chinese government is also investing heavily in research into renewable energy. However, as factories continue to be built, requiring power which still largely comes from coal-powered electricity, emissions continue to rise.

As the population becomes richer, pollution levels are likely to rise still further through increased car ownership and the use of more appliances.

Pollution in China: are we to blame?

While it is easy to think these environmental issues are entirely the fault of the Chinese and their government, in reality it is more complex than that. Our desire for cheap products means companies in Australia and other countries have their goods made in China. So by buying those goods we are, in some respects, responsible for at least some of this damage. It is important to remember that we live in an interconnected world: the decisions and choices we make have impacts in other countries.

Industry and regional growth in China

As this chapter has already stated, manufacturing has been hugely important to the national economy of China. These industries have also transformed entire regions, raising standards of living and changing the way of life for inhabitants.

While Silicon Valley’s growth has been led almost entirely by companies and private investment, with little planning, China’s central government has carefully planned the growth of specific regions, providing the conditions for industry to succeed.

The future of manufacturing in China

China’s rise in terms of industrial output has been spectacular, but it is not clear what the future will hold. There are a range of factors that may affect its performance.

Environmental concerns

The chapter has already explored the problems of air and water pollution in China. Environmental pollution has started to affect productivity in many regions as workers become sick, and the costs of cleaning up polluted areas are immense. The need for cleaner power is also affecting their future.

While giant hydro-electric power (HEP) schemes such as the Three Gorges Dam are meeting some needs, yet more power will be required – and it is likely to come from polluting sources such as coal.

The threat of other countries

As the level of manufacturing in China has increased, the country has become wealthier and wages have increased. This has led to costs in Chinese factories also rising, which means they have become less competitive compared with poorer nations such as the Philippines, Thailand and India. These nations are increasingly rivalling China in lower technology manufacturing such as textiles and plastics.

Hi-tech industries

Many regions in China are now investing in hi-tech factories that produce goods with much higher retail value. This increases profitability, because of the greater difference in these companies (from Western companies, which pay higher wages) between the cost of production and the price for which the product is sold. China has an increasing number of highly skilled workers who are graduating in fields such as IT and engineering, and they are increasingly employed in these types of industries.

The development of the interior of China

With almost all the major industrial hubs located on the coast, there is potential for more industries to be located in the middle of the country, where there is more land available and cheaper labour.

This may allow China to remain competitive with its rivals.